Green energy for the future

L&L is the first Italian company involved in the production of sustainable biomethane for transport, a strategic vector for the decarbonization of mobility and the energy transition to renewable sources. The Group, in partnership with Green Arrow Capital, has launched an industrial project of 6 biomethane production plants, located in Italy, and three service stations for the direct sale of liquefied biomethane, also known as “bio liquefied natural gas” or “bio-LNG”. In operation 24 hours a day, seven days a week, with a production capacity of 300 cubic meters per hour, each plant can treat 47,000 to 50,000 tons of livestock mianure and agricultural biomass per year, producing an annual 1,800 tons of biofuel. The annual production of each plant can, therefore, power more than 1,800 vehicles, and save the consumption of 2,000 tons of oil, and the associated atmospheric carbon dioxide emissions. This means reducing atmospheric carbon dioxide emissions by as much as 4000 tons per year per plant.

Biomethane is a clean and programmable energy resource, making it possible to meet the objectives of reducing climate-altering emissions and promote energy independence from fossil fuels. Produced from the treatment of agro-zootechnical biomass, biomethane can be introduced in gaseous form into the national gas network, or made liquid at source using liquefier technology and distributed as a biofuel to refuelling stations.

How is L&L’s biomethane made?

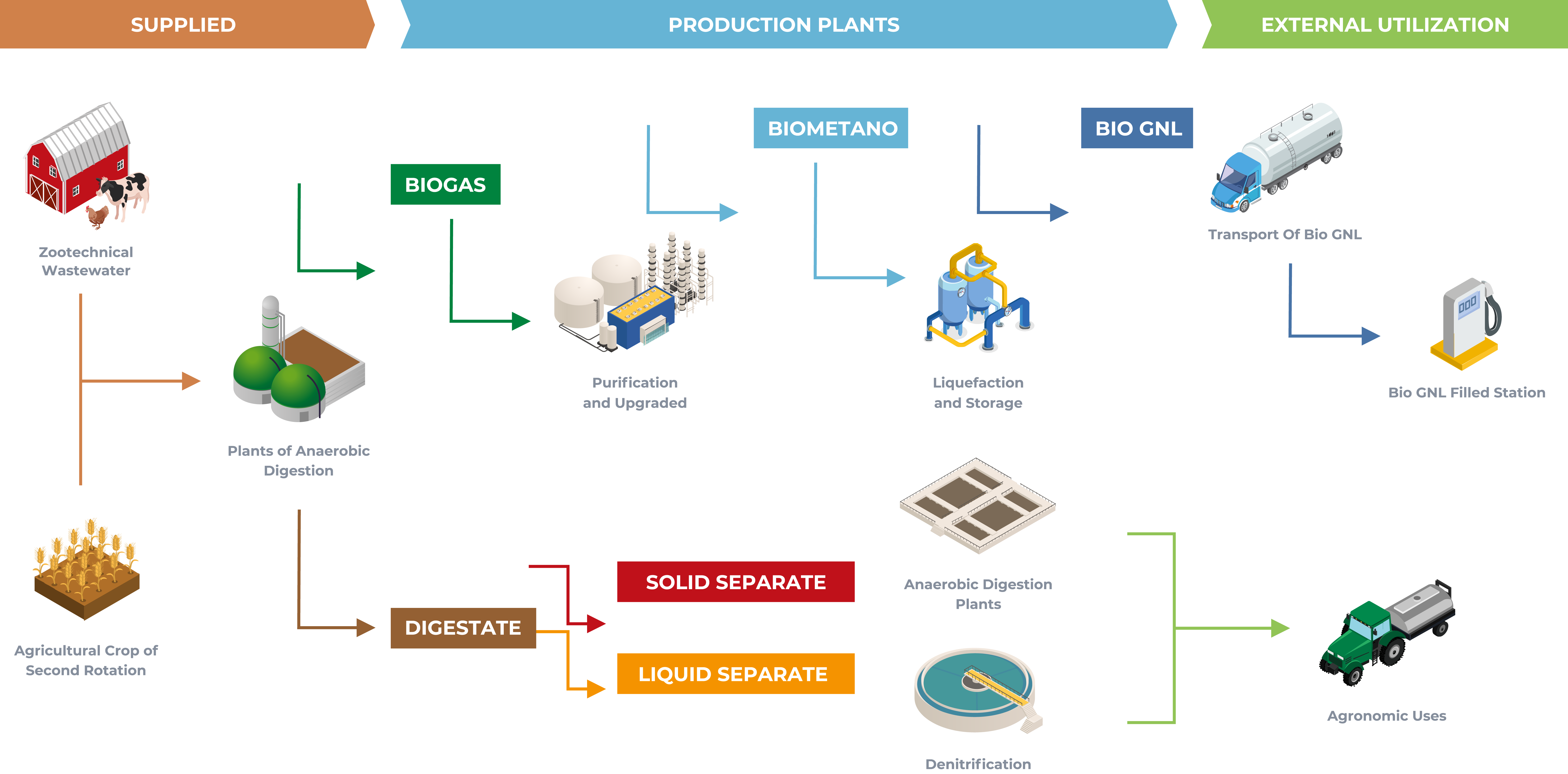

The biomethane comes from the decomposition and fermentation of biomass. The processing plant is fed continuously. For this reason, one of the most important phases of the process is the continuous input of livestock manure from cattle and poultry and agricultural biomass, such as triticale and sorghum, not intended for human consumption, and left to ferment in anaerobic digesters. In the complete absence of oxygen, biogas is produced, which is relatively low in energy, containing only 40 to 60% methane, 40 to 60% carbon dioxide, and some traces of other compounds including hydrogen sulfide. The biogas is then purified via an upgrading system, to eliminate carbon dioxide and other polluting compounds.

The digestate, that is the residue of the biogas formation process, undergoes a liquid and solid separation phase. From this last processing step, solid digestate is obtained, useful for the production of biofertilizers, such as mixed compound amendent and organic nitrogen fertilizers, excellent alternatives to chemical fertilizers, and, therefore, suitable for organic and sustainable agriculture. The liquid digestate, on the other hand, treated with a nitro-denitro system, is collected by local farmers and distributed over cultivated land. The system designed by us thus ensures a reduction of nitrogen of no less than 50%.

The production of mixed compound amendment and nitrogen organic fertilizers is delegated to our Group company, L&L Fertilizzanti.

THE ADVANTAGES OF BIOMETHANE

Circularity of resources

Agricultural biomethane produced from local livestock manure and agricultural by-products promotes the circularity of resources, and thus becomes an essential tool in reducing the environmental impacts of agricultural practices.

Sustainable innovation

The biogas produced is purified and treated through upgrading, a cutting-edge technology for the removal of carbon dioxide.

Air quality improvements

It is scientifically proven that advanced biomethane used in transport reduces emissions of nitrogen dioxide, an air pollutant produced by other road traffic and other fossil fuel combustion processes.

A programmable and adaptable resource

Biomethane can be transported using existing gas infrastructures, for subsequent use in transport and heating and cooling, in the residential and tertiary sectors, or in industrial processes.

THE CYCLE OF PRODUCTION OF THE BIOMETHANE PLANTS

The plants for the production of biomethane, projected by L&L, will have the capacity to product 300 Smc/h (300 cubic metres per hour), started from the biogas obtained from the anaerobic digestion of zootechnical wastewater and agricultural crop of second rotation. The produced methane will be entered in the SNAM net.

L&L Biomethane Plants

Bio Verola (BS)

Biomethane Plant Bio

Bio Industria (BS)

Biomethane Plant Bio

Gambaresca (BS)

Biomethane Plant Gambaresca

Bio Tre Ponti (BS)

Biomethane Plant Bio

Bio Sole (BS)

Biomethane Plant Bio

Bio Gottolengo (BS)

Biomethane Plant Bio